In the world of precise measurements, 150 meter calipers stand out as essential tools for various industries. This comprehensive guide explores the functionality, features, benefits, and practical applications of these indispensable instruments, providing valuable insights for professionals and enthusiasts alike.

Understanding 150 Meter Calipers

150 meter calipers are precision instruments designed for measuring lengths up to 150 meters with high accuracy. These calipers are commonly used in industrial, construction, and research settings to ensure exact measurements of large-scale components and distances.

The basic functionality of 150 meter calipers involves a sliding scale that allows users to gauge the distance between two points. Key components include the main scale, a vernier scale for enhanced accuracy, and a locking screw to secure the measurement.

Features of 150 Meter Calipers

One of the primary features of these calipers is their extensive measurement range, which can cover distances up to 150 meters with high precision. Accuracy is paramount, often down to fractions of a millimeter, ensuring reliable results.

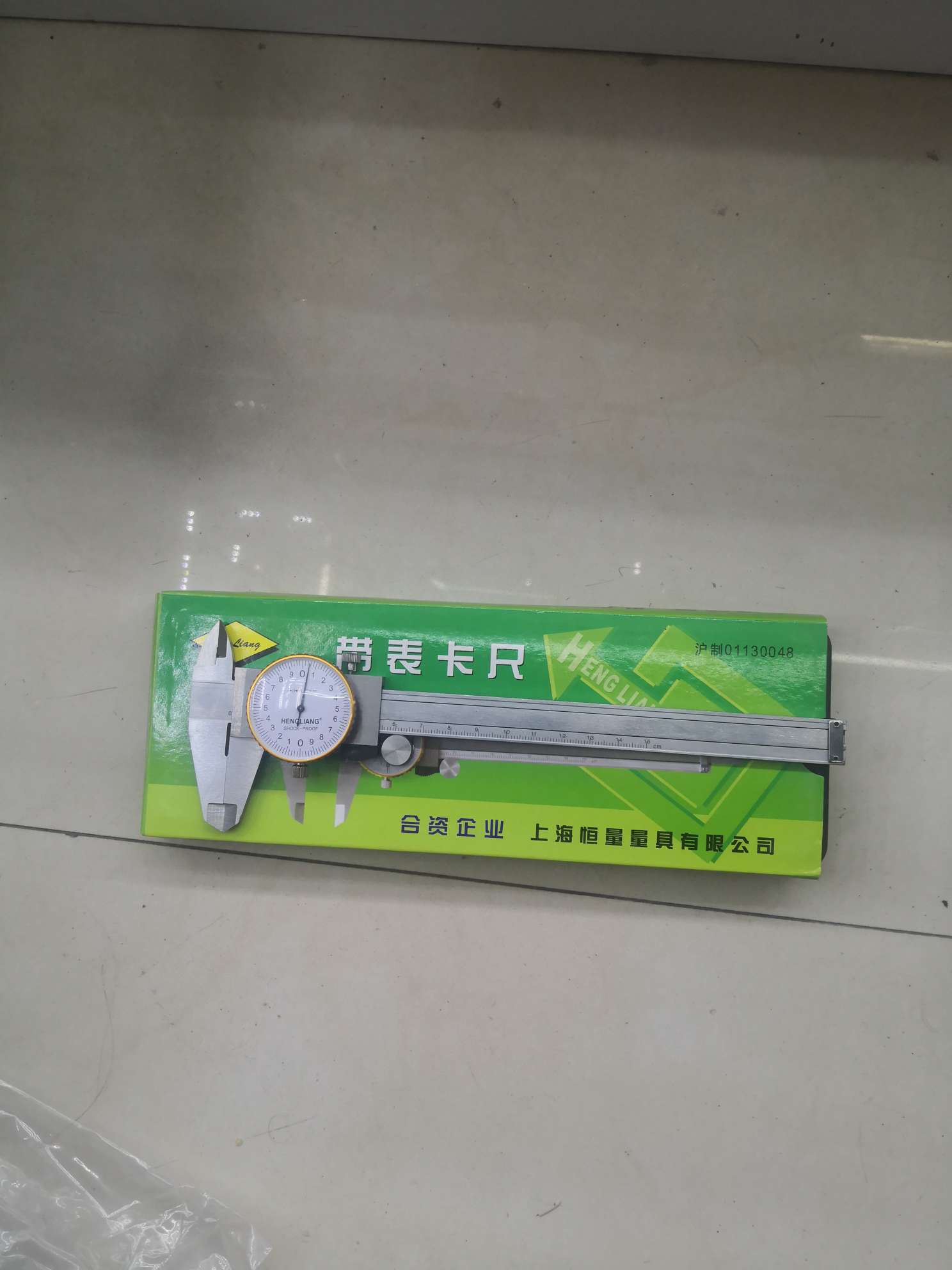

Users can choose between digital and analog displays. Digital calipers offer easy-to-read measurements and often come with additional features like data storage and transfer capabilities. Analog calipers, on the other hand, are valued for their simplicity and durability.

Material and durability are critical considerations. High-quality calipers are typically made from robust materials like stainless steel, ensuring longevity even in demanding environments. Regular calibration and maintenance are necessary to maintain accuracy and extend the lifespan of the instrument.

Benefits of Using 150 Meter Calipers

The foremost benefit of using 150 meter calipers is the enhanced precision they provide for large-scale measurements. This precision is crucial in industries where even minor discrepancies can lead to significant issues.

These calipers also save time and increase efficiency. By providing quick and accurate measurements, they reduce the need for repeated checks and adjustments, streamlining workflows.

Versatility is another advantage. 150 meter calipers are used across various industries, from industrial manufacturing and construction to research and development. Their cost-effectiveness over time makes them a worthwhile investment, as they reduce material waste and improve quality control.

Practical Applications

In industrial manufacturing, 150 meter calipers play a crucial role in quality control on production lines, ensuring components meet precise specifications. They are also used to measure large machinery components, aiding in the assembly and maintenance of complex machines.

In construction and engineering, these calipers are indispensable for site measurements and layout planning. They help verify the dimensions of structural components, ensuring buildings and infrastructure are constructed accurately.

For research and development, 150 meter calipers assist in prototyping and design testing. They enable precise experimental measurements, facilitating innovation and development in various fields.

Choosing the Right 150 Meter Caliper

When selecting a 150 meter caliper, consider factors such as your measurement needs, environmental conditions, and budget constraints. Evaluate popular brands and models, comparing features and prices to find the best fit for your requirements.

Read user reviews and ratings to gain insights into the performance and reliability of different calipers. This feedback can be invaluable in making an informed decision.

Tips for Effective Use

Proper handling techniques are essential to ensure accurate readings. Always handle calipers with care, avoiding drops or impacts that could affect their precision.

Regular calibration is necessary to maintain accuracy. Follow the manufacturer's guidelines for calibration practices and schedule routine checks.

If you encounter common issues, such as inconsistent readings or difficulty in locking measurements, consult the user manual or seek professional assistance for troubleshooting.

Future Trends in Measurement Instruments

Technological advancements continue to enhance measurement instruments. Integration with digital tools and software allows for more efficient data management and analysis.

Emerging standards and regulations ensure that measurement instruments meet high accuracy and reliability criteria, promoting consistency across industries.

Case Studies and Testimonials

Real-world examples highlight the practical benefits of using 150 meter calipers. For instance, a manufacturing company improved their quality control process, reducing defects and increasing customer satisfaction.

Industry professionals praise the reliability and precision of these calipers, emphasizing their role in achieving high standards of accuracy in various applications.

Frequently Asked Questions

Common inquiries include how to calibrate 150 meter calipers, the differences between digital and analog models, and tips for maintaining accuracy. For additional resources, consult manufacturer websites and industry publications.